The packaging of a product plays a critical role in shaping customer perceptions and establishing a brand’s identity. It serves not only as a protective layer but also as a powerful tool for communicating key product information, ensuring that customers can easily identify and understand what the product offers. A well-designed package reflects the brand’s values and personality, making it an essential element for conveying the brand’s unique story. High-quality, aesthetically pleasing packaging elevates the overall presentation of the product, enhancing its appeal and creating a lasting impression.

Now, we will talk about the main structures of packaging boxes. Let’s explore them together.

Common Tube Packaging Box Structure Designs

Box Lid Structures

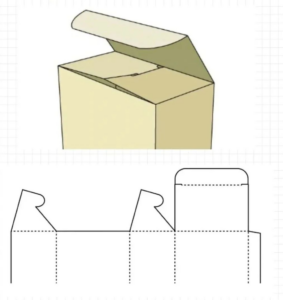

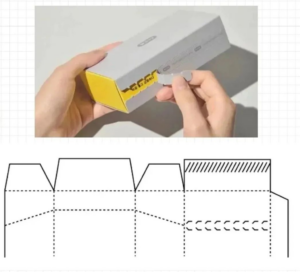

1、Flip-Top Insert Style

The lid has three flip-top parts, with the main lid featuring an extended tab that inserts into the box to achieve a sealing function. When designing this structure, attention must be paid to the engagement between the flip-top parts. This is the most widely used structure in tube packaging boxes.

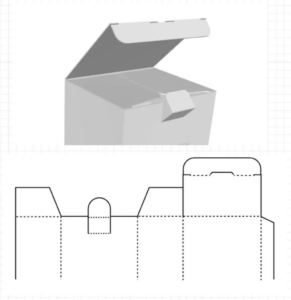

2、Locking Mechanism Style

The locking structure involves the flip-top on both the front and back sides, which interlock to create a secure closure. While this structure is firm, assembly and opening can be a bit more complicated. It’s suitable for a wide variety of applications.

3、Double Lock Flip-Top Insert Style

This packaging design utilizes double engagement to ensure that the flip-top is securely locked. The tab and the lid’s engagement point can be omitted for more convenient repeated opening and closing, making it ideal for bulk food packaging.

4、Adhesive Sealing Style

This sealing method is highly effective, ensuring good airtightness and is suitable for automated machine production, though it cannot be resealed. It’s primarily used for packaging powdered or granular products, where once opened, the packaging cannot be reused.

5、Single-Use Anti-Counterfeit Style

This packaging design uses serrated cutting lines that break when the consumer opens the package, preventing reuse for counterfeiting. These are typically used for pharmaceuticals and small food products.

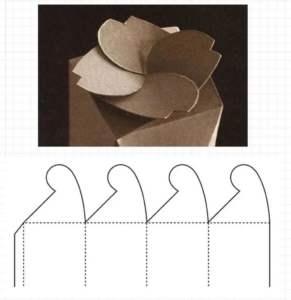

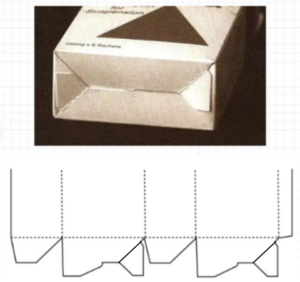

6、Continuous Flip-Top Nesting Style

This is a decorative and aesthetically pleasing locking structure, though it requires manual assembly and opening. It’s ideal for gift packaging, especially for souvenirs, holiday gifts, etc.

Box Bottom Structures

The box bottom supports the weight of the product and requires certain load-bearing capacity. Common designs include:

1、Flip-Top Double Insert Bottom

The structure is identical to the flip-top insert lid and is easy to use. However, it has a lower load-bearing capacity, making it more suitable for lightweight products like food, stationery, and toothpaste.

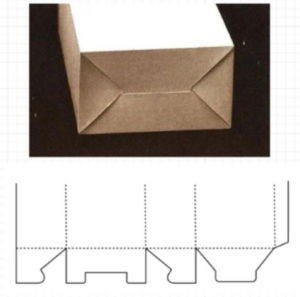

2、Self-Locking Bottom Style

This bottom structure uses four flip-out parts that interlock by a “hook and insert” method. It’s easy to assemble and offers moderate load-bearing capacity.

3、Auto-Lock Bottom (Self-Sealing Bottom Box)

This design uses pre-adhesive processing, allowing the bottom to lock automatically when the box is opened, which is highly convenient, time-saving, and sturdy. This structure is typically used for packaging heavier products in automated production settings.

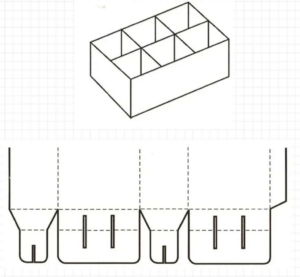

4、Partitioned Sealing Bottom

This design forms partitions inside the tube packaging, effectively separating and securing the product, providing better protection. The partitions are integrated with the box body, saving cost and offering a higher compressive strength.

Top and Bottom Box Lid Structure

The top and bottom lid packaging box, also known as the “box lid”, is made up of a box lid and a box body that are buckled together. The box lid is called the “top lid” and the box body is the “bottom lid”. As a classic style in the packaging industry, the top and bottom lid gift box is well compatible with food, skin care products, electronic products, etc.

1、Top and Bottom Box Style

This classic design consists of a top lidand a bottom body. It’s widely used for packaging food, skincare products, and electronics.

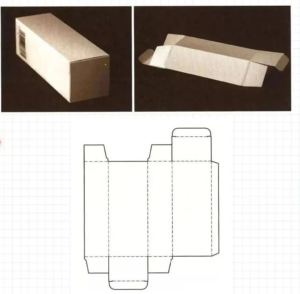

2、Single-Piece Paper Box

This box can be shipped flat, saving on transportation costs, but requires manual folding for assembly.

3、Corrugated Paper Box

Commonly used for fruit boxes, it features hand holes and ventilation holes. The corrugated material provides excellent compression and impact resistance, making it suitable for storage and transport.

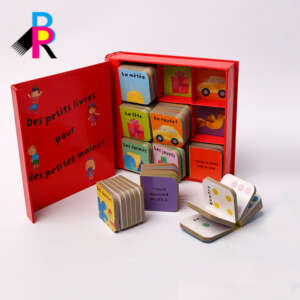

4、Premium Box Style

These premium top-and-bottom boxes are made with hardboard and are customized with inner trays to enhance the product’s presentation. With the rise of automated production, manual assembly is no longer necessary, boosting efficiency and reducing costs.

Drawer Box Structure

Drawer boxes consist of an inner box and an outer sleeve, offering an elegant unboxing experience. They are suitable for most product categories.

1、Single-Piece Drawer Box

Made from materials like white card, black card, coated paper, and special papers. It’s often used for simple gift packaging.

2、Corrugated Paper Drawer Box

Made from corrugated materials with various flute types (e.g., A flute, B flute, C flute). It’s widely used for shipping and storage packaging.

3、Premium Drawer Box

Made from high-end materials like velvet, leather, and specialty papers, often used for luxury product packaging.

4、Multi-Layer Drawer Box

This design consists of two or more inner boxes, separated by dividers for better organization.

5、Fan-Shaped Drawer Box

The fan-shaped drawer box provides a unique, interactive experience when opened.

6、Display Drawer Box

This structure includes two outer doors and a central inner box for display purposes, creating a visually appealing presentation.

Folding Box Structure

Folding boxes are increasingly popular due to their ability to reduce logistics and storage costs. They also offer the advantages of low production cost, ease of sale, and reusability, making them a favorite of both brands and consumers.

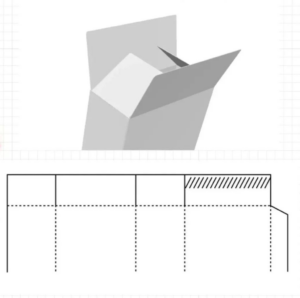

1、Single-Piece Folding Box

The single-piece folding box, also known as the classic export folding box, is similar to a book-style box. It typically consists of a skin shell and side wings, with additional components like magnets, metal sheets, and inner linings.

2、Two-Piece Folding Box

Made from just two cardboard pieces, this structure is efficient to assemble and is often used for simple, environmentally friendly packaging.

3、Seven-Piece Folding Box

A more complex folding box structure, which includes additional flaps and tabs for securing the box. Though more expensive, it offers better support and durability.

4、Side-Folding Box

This design uses a side folding method where the bottom of the box is pre-glued for easy assembly. It is simple to produce and cost-effective.

Other Packaging Structures

1、Magnetic Closure Box

These boxes use magnetic flaps to secure the lid, making them perfect for luxury items like jewelry and cosmetics.

2、Handheld Boxes

These boxes feature built-in handles for easy transport. They are widely used in industries like food packaging and gifting.

3、Custom-Shaped Boxes

Packaging that matches the unique characteristics of the product, enhancing both aesthetics and customer appeal. Custom shapes like pentagons, hexagons, and even diamond-shaped boxes are designed to attract consumers’ attention.