In our blog, Using Pantone Colors for Packaging and Branding, we discussed the Pantone Matching System (PMS) and mentioned three other business-relevant color systems. Those are CMYK, RGB and HEX.

We also pointed out that the PMS and CMYK were mostly used for printing, whereas RGB and HEX were more for digital graphics. However, missing from that discussion were comparisons between the PMS and CMYK on one hand, and RGB and HEX on the other.

In this blog, we explore these topics further to note their differences and general uses in business. But first, there is something we need to get out of the way.

What Is The Difference Between Spot And Process Colors, And Why Does It Matter?

Should I Use Pantone Colors or CMYK for Printing?

How Can the RGB System Help Me with CMYK Printing?

What Is the Difference Between the RGB and HEX Systems?

What Is The Difference Between Spot And Process Colors, And Why Does It Matter?

In our previous Pantone colors blog, we mentioned that using Pantone colors for printing is more expensive than using CMYK colors. This is because the final print color is determined differently in each case.

Pantone colors are spot colors. The inks are premixed before they are used. You can already see a solid color after only one pass of the machine. What you print on the spot is the final color, and nothing else will be applied on top of it. If a graphic has multiple colors, they will all require different inks.

Spot colors are great for projects needing only a few hues on one surface, like when you’re printing a logo or painting a house. Not only do you save time applying color in one stroke, but you also ensure that its reproduction is precise. If you’re using Pantone colors, you even have the option to use metallic, neon and pastel shades.

But what happens when you need to print a real-life picture, where shadows create a lot more color variations on one surface? Spot coloring will be impractical for such a purpose.

This is where process colors come in. Process printing involves different ink sources that do not produce solid colors after one run. You cannot appreciate the final colors until the process is complete.

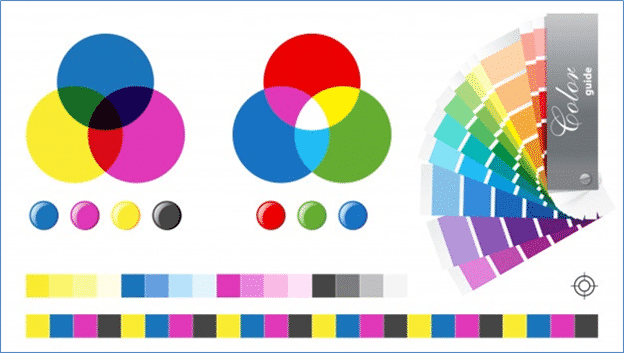

CMYK colors are process colors. “C” stands for “cyan.” “M” stands for “magenta.” “Y” stands for “yellow.” “K” stands for the “key plate,” which normally has black ink or whichever is the darkest color in use. Conventionally, “K” is assigned to black in CMYK to avoid confusion with blue in RGB. All other inks align with the key plate.

Get 10% OFF for each COLOR!

What happens during process printing?

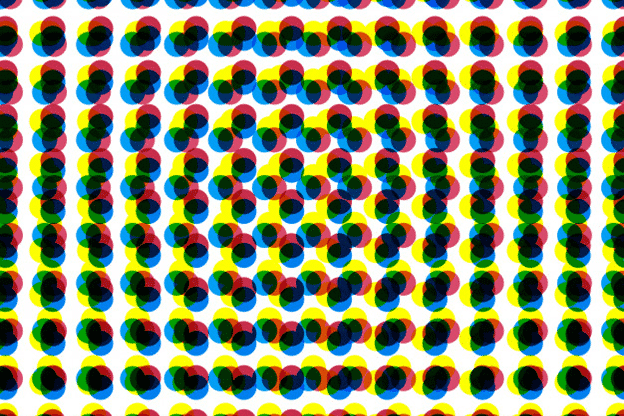

- Microscopic dots are deposited on paper coming from each ink source. In the CMYK system, the inks are colored cyan, magenta, yellow and black.

- The dots are deposited at different angles and in varying quantities. The amount of ink used in a given section may be expressed as “dots per inch” or “dots per millimeter.”

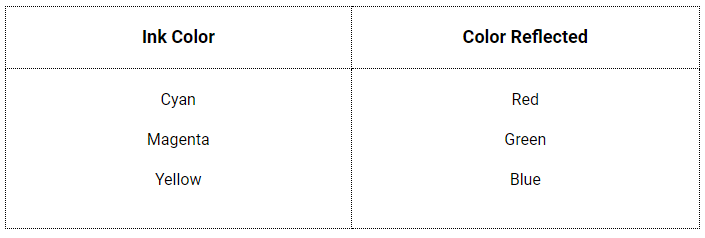

- The combination of these elements creates illusions of multiple solid colors. The black dots, which usually predominate when printing text and real-life photos, are produced by the key plate and imprint the image detail. The cyan, magenta and yellow inks reflect their complementary colors. Cyan reflects red. Magenta reflects green. Yellow reflects blue.

- The colors you see are combinations of these reflected colors. Color intensity depends on the proportion of ink applied.

Since colors and contrasts adjust during process printing, the technique enables creating text and real-life pictures cost-efficiently and fast. However, since only four base colors are used in CMYK, it cannot simulate all Pantone colors, especially the metallic, neon, and pastel tones.

It pays to know these things, even on a basic level. The information will let you optimize your resources and communicate better with your packaging and product designers.

Should I Use Pantone Colors or CMYK for Printing?

It really depends on the task.

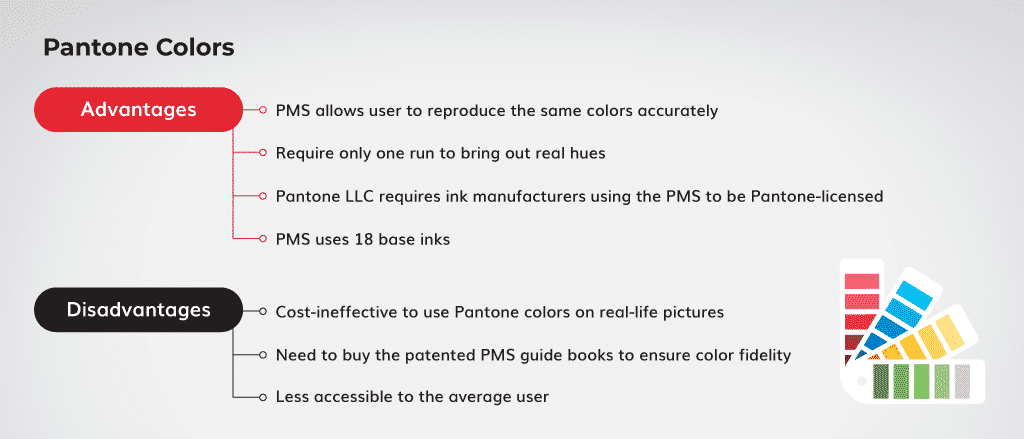

Pantone colors have the following advantages when used:

- The PMS allows you to reproduce the same colors accurately. This makes Pantone colors great for branding, where the slightest deviation in packaging or label appearance can ward off customers.

- Pantone colors, being spot colors, need only one run to bring out real hues. This makes them great for applications like architecture, cosmetics, hand paintings, furniture painting, clothes, etc. Imagine if you used CMYK plates for these tasks!

- Pantone LLC requires ink manufacturers using the PMS to be Pantone-licensed. The manufacturers need to submit base ink samples yearly to make sure that they stay within Pantone standards. This ensures that all PMS colorants around the world are standardized.

- The PMS uses 18 base inks, forming the 1,867 standard Pantone print colors currently in existence. They include metallic, neon and pastel colors. A wide range of custom colors can be made by combining the standard ones. They are best used for projects requiring hues beyond the CMYK range.

On the other hand, Pantone colors have the following disadvantages, too:

- As mentioned earlier, it would be cost-ineffective to use Pantone colors on real-life pictures because of the sheer number of shades needed. The same goes for text printing, but this is because Pantone inks are generally more expensive than CMYK colorants. Additionally, changing inks requires washing up plates, so spot-printing graphics with many colors will also be very time-consuming.

- You need to buy the patented PMS guide books to ensure color fidelity, and they tend to be pricey. This is practical only for ink manufacturers and printing services.

- Spot color printing is less accessible to the average user, e. g. an entrepreneur not engaged in the printing trade. Spot colors require special printing machines.

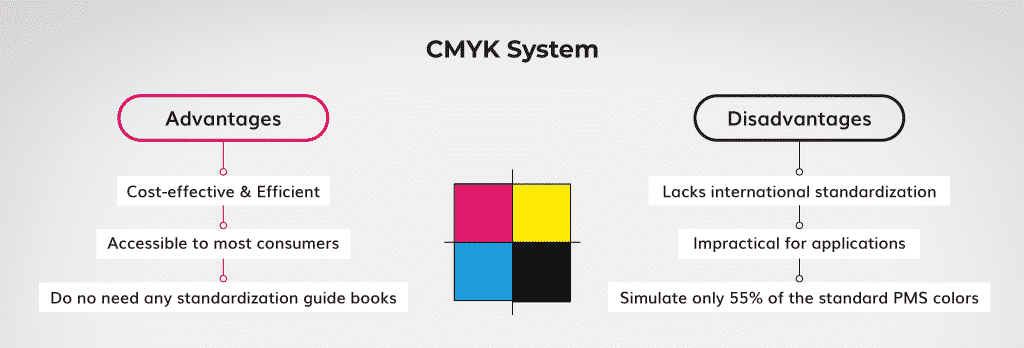

Meanwhile, the following are the CMYK system’s advantages:

- It is cost-effective and efficient for creating real-life pictures and text. The printing process determines the final image colors.

- It is accessible to most consumers. Aside from printing presses, home and office printers also make use of this system. You must have seen the CMYK designations whenever you buy ink for your inkjet, toner for your laser or ribbon for your thermal transfer printer.

- There is no need to buy any standardization guide books, helping to further reduce costs.

However, these are the CMYK system’s disadvantages:

- It lacks international standardization. Different CMYK ink producers, e. g. HP, Epson, Brother, etc., arbitrarily make their own formulations. Therefore, CMYK printing will be risky for branding. Imagine if Coca-Cola’s label did not appear in the standard red from batch to batch if the company used CMYK.

- Process coloring is impractical for applications where a single ink or paint run will suffice, such as fashion items, furniture, infrastructure, etc.

- CMYK can simulate only 55% of the standard PMS colors. Pantone LLC created the CMYKOGV extended gamut, which added orange, green and violet to CMYK. This allows the simulation of 90% of standard PMS colors during process printing.

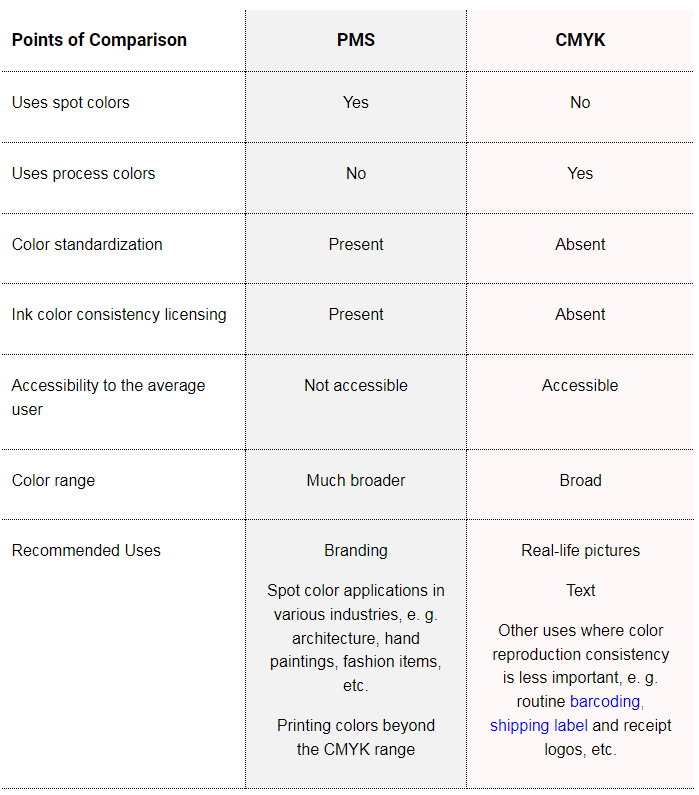

Here is a table comparing the two systems side by side in terms of their uses in printing:

The color system you will use will depend on the application it will be used for. So, one is not necessarily better than the other.

How Can the RGB System Help Me with CMYK Printing?

The RGB—or red, green and blue—color system is one that is used for images on television and electronic gadget screens. It has a coding system different from the PMS and CMYK, but there are ways to convert these codes from one to another.

To explain how RGB works, we must go back again to light optics like we did in Barcode Basics: A Simplified Guide for Startups.

Remember the colors of the rainbow?

Those colors originate from a light source, the sun. Their appearance indicates changes in the direction and speed of light as it passes through two materials, which, in this case, are air and water (raindrop). These changes cause white light to separate into its component colors: red, orange, yellow, green, blue, indigo and violet.

Note that we called these rainbow-colored lights “components” of white light. When the process is reversed, and these rays are combined, white light appears again.

Where do we see this reverse process commonly occurring? Where else, but in our electronic gadgets and television sets, which are black when the power is off? When activated by electricity, different light rays form, which can produce white light when combined.

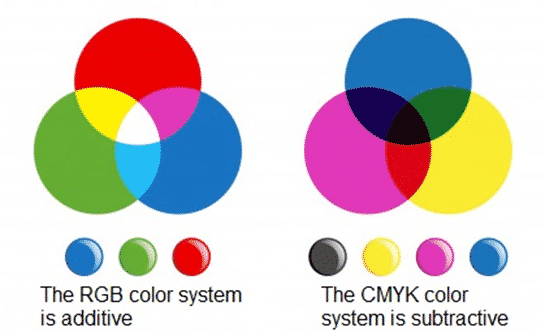

This “additive color system” exists only when there is a light source, and it is the basis of the RGB system.

Compare that to what happens during CMYK printing. There is no light source, but our starting point is white paper.

The following things happen when ink is deposited on paper:

- The paper’s whiteness decreases. Put in another way, it darkens.

- When light shines on the ink, the color we perceive is a reflected color. On the color wheel, this reflected color is the ink’s complementary hue. Applied to the RGB and CMYK systems, we have the following:

- As we pointed out in our barcode basic guide, black only absorbs light and does not reflect it.

- The more colors you put on one spot, the darker the spot will get. This is the opposite of what happens when you combine different colored lights. This is a “subtractive color system,” which is the crux of CMYK.

- Theoretically, you can get black by simply combining cyan, magenta and yellow. But in real life, the process is not perfect, so a muddy brown is instead produced. Also, there is a risk of bleeding and tearing the paper when too much ink is applied to one site. So a separate black color is necessary when printing simple black text or graphics. However, richer tones can be achieved by combining black with CMY colors.

Now, how will you apply this knowledge to printing?

All of this matters when you’re translating a digital image into print, and you want to preserve the color intensity.

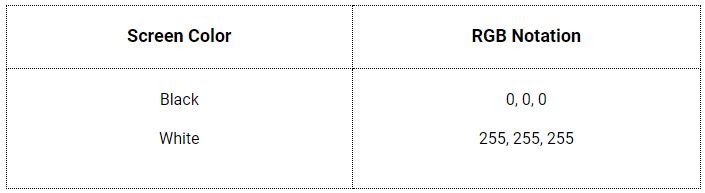

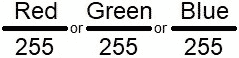

In the RGB system, color intensity is assigned a value of anywhere from 0 to 255. When all three components have a 0 value, the color black is produced. Setting all three to 255 produces white light. Hence, in RGB notation, we have the following for codes for black and white:

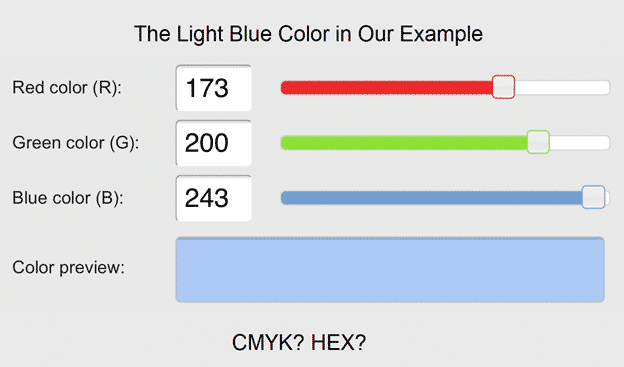

Other colors are formed by combining red, green and blue in various proportions. For example, on Microsoft Word, the RGB notation (165, 200, 243) specifies a light blue shade.

RGB colors can be translated into CMYK codes, which home and office printers do automatically right before printing. However, since RGB is an additive system and CMYK is a subtractive one, what looks bright on a computer screen may look dull in print. Besides that, the conversion process is not always straightforward because of CMYK’s range limitations.

There are ways to smoothen these problems, though.

The first one is to switch from RGB to CMYK when using design software. Adobe apps like Illustrator, InDesign and Photoshop have this convenient feature.

The second one is to use online conversion tools, such as an RGB calculator.

The third one is the toughest, as it requires manually deriving the numerical values. You may skip this part and move on to the next section if you don’t like math.

If you have RGB values, you can compute for the cyan, magenta and yellow color codes by following the steps below.

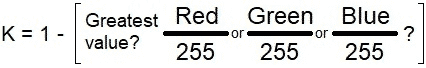

First, determine the K-value. To do this, find out which among these three fractions has the greatest value:

Then calculate K. The highest value among the three fractions becomes the second term of this formula for K:

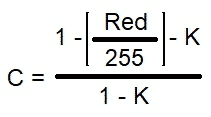

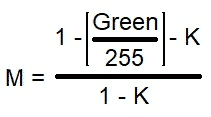

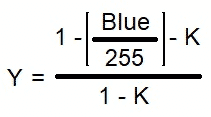

From this, the values for cyan, magenta and yellow can be derived as follows:

Note that CMYK values are fractions of 1. When multiplied by 100, they give you % values.

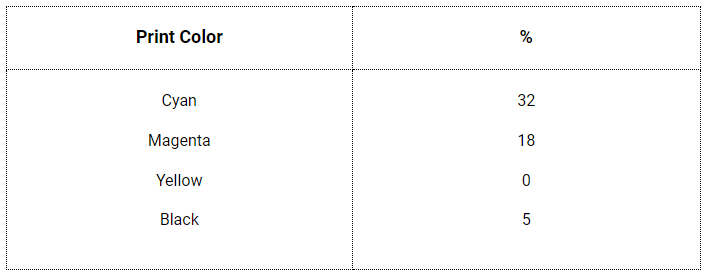

For the light blue color we picked earlier that has the RGB code (165, 200, 243), the blue fraction has the highest value, 243/255 = 0.95. This makes K = 1 – 0.95 = 0.05. If you plug this into all the other equations, the CMYK values should be:

Again, you can avoid this tedious process by getting the codes from an appropriate design app or online RGB calculator. Once you obtain them, you can use them on your own printer or give them to your preferred printing service along with your order.

What Is the Difference Between the RGB and HEX Systems?

The HEX and RGB systems use the same color space, but HEX encodes RGB values differently. It is dependent on the hexadecimal system and not the good old decimal system that we’re accustomed to and that the RGB system uses.

The HEX coding system is used more often for web design than RGB because of the following advantages:

- HEX codes are more compact. They are composed of a hashtag and six HEX digits, unlike RGB codes, which are written separately and can have more than two digits each. In some cases, HEX codes can further be contracted to just a hashtag followed by three digits.

- HEX codes are easier to copy and encode because they occur only as a single string, unlike RGB codes.

- Computers work faster using the HEX coding system than RGB. HEX speeds up webpage loading time.

However, these differences have become less significant in the last few years because of continuing software improvements. Hence, both HEX and RGB systems are widely used for web design.

Web design software and online HEX translators can help you convert one to the other and vice versa easily. However, as in RGB-to-CMYK conversion, you can also compute the values on your own.

Again, if you don’t like math, you can just skip this part of the discussion and get your values from an online HEX translator or appropriate design software.

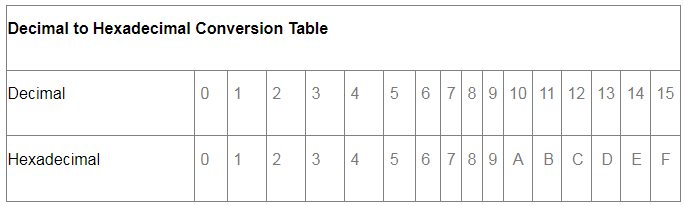

In the hexadecimal system, only the numbers 0-9 and letters A-F are used. Their equivalents in the decimal system are in this table:

For the blue color in our example, let’s convert the RGB code to its HEX equivalent. Again, the RGB code is (165, 200, 243).

First, we take the R-value 165. We divide this by 16. Doing so yields 10 remainder 5. The hexadecimal equivalent of the whole number 10 is A, and that of the remainder 5 is 5. Therefore, the red component’s HEX code is A5.

Then we do the same calculations for G and B. For G, we get 12 remainder 8, which translates to C8. For B, we get 15 remainder 3, yielding F3.

Therefore, the HEX code for this blue color is #A5C8F3. Did you get the same?

For the color white, the HEX code is #FFFFFF. Meanwhile, the HEX code for the color black is #000000.

Computations like these are practical to use when you have only a few colors to work with. If that’s the case, you should consider printing with Pantone colors instead of CMYK to get the best quality. Conversion to Pantone colors can be done using the Pantone Color Finder or one of the PMS guide books.

Conclusion

The PMS, CMYK, RGB and HEX systems are color spaces used in various aspects of business. Pantone and CMYK colors are used for printing, whereas RGB and HEX are for digital images. Conversion from one system to another helps bring digital designs to life and vice versa.

Familiarization with these systems can help business owners understand some technical aspects of printing and web design. This information is important as it can help avoid unnecessary costs and delays.

Source: enkoproducts